Accesories

Wire rope clips

Product details

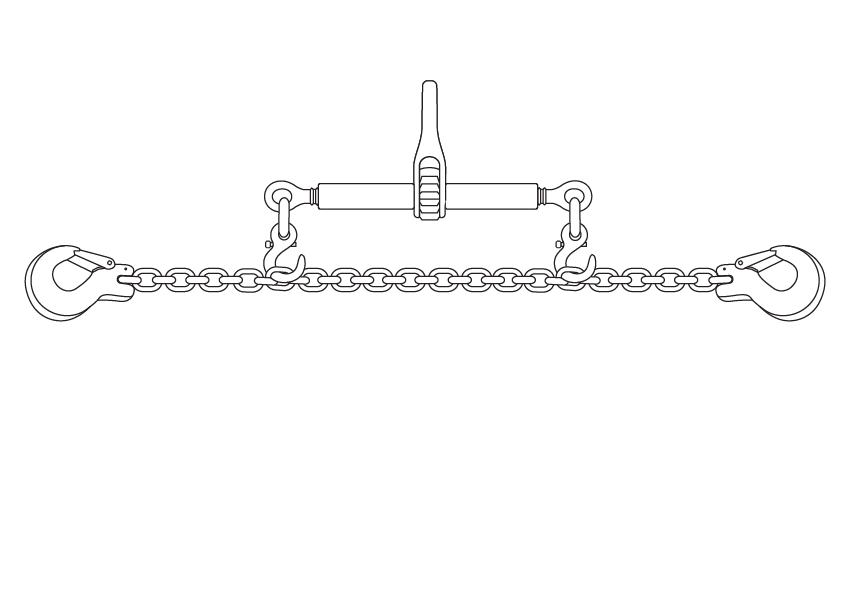

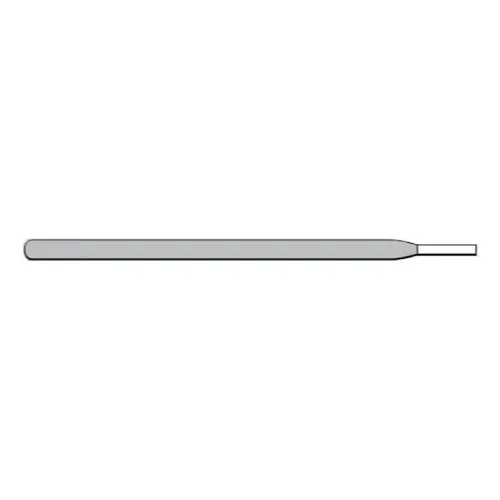

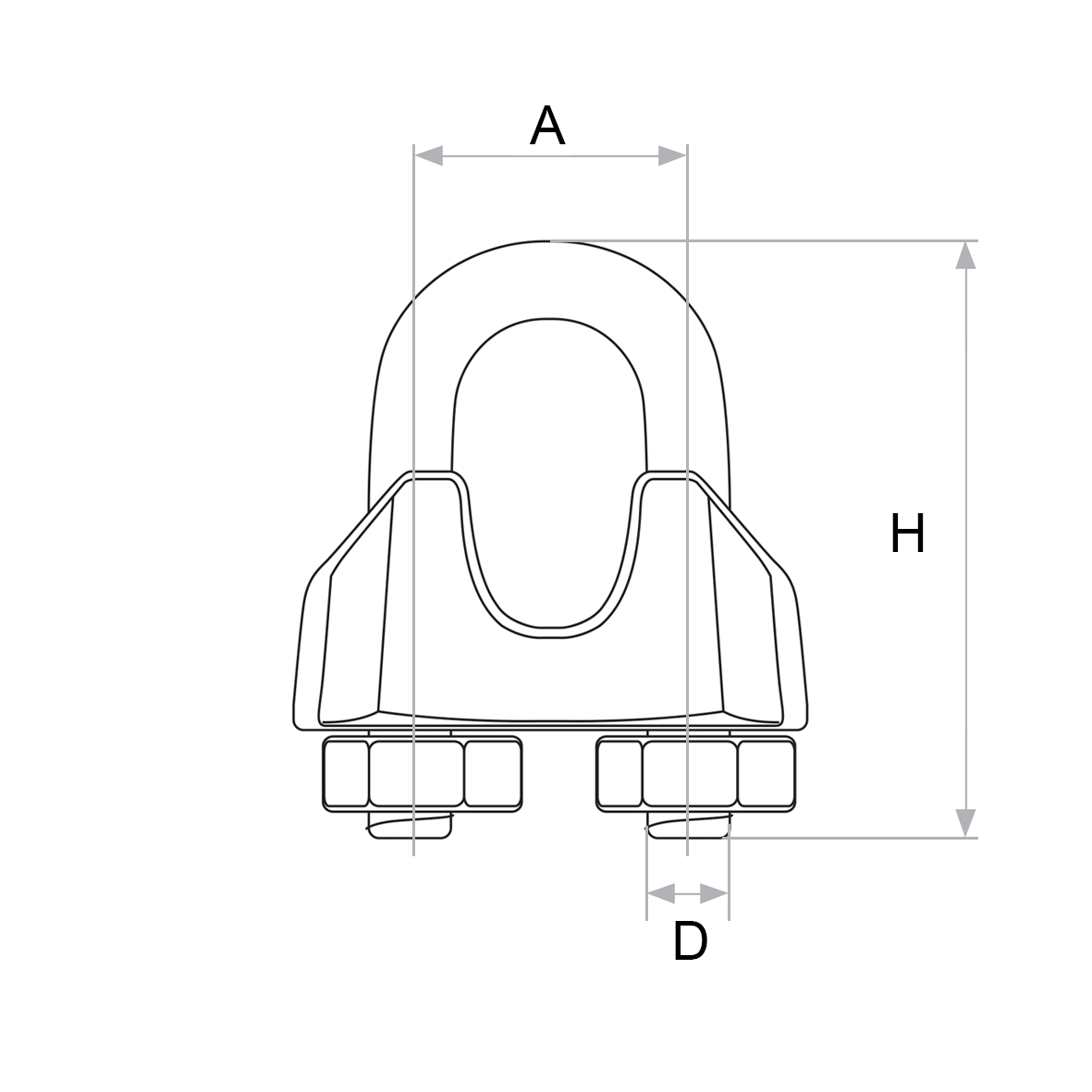

Wire rope clips are designed for manually securing a cable loop (eyelet); for better securing of the cable loop, at least three clamps should be placed next to each other; the table below shows recommendations regarding the minimum number of clips depending on the cable size. Components: threaded loop at the ends, forged body, fastening nuts. For better securing, it is recommended to install the clips with the body positioned along the active end of the cable (*). The clips must not have cracks or defects. The zinc coating must uniformly cover all surfaces. The coating is done either by electrolytic zinc plating or hot-dip galvanizing, as applicable.

These products are delivered in boxes containing a specific quantity per box; the delivered quantities will be rounded to ensure complete boxes are delivered. The quantities per box differ depending on the supplier, generally multiples of 10 pieces. If you request information about the delivered quantity, please request this in the order form in the order details. Wire rope clips are supplied upon request in accordance with the standard requirements according to DIN 741 or EN 13411-5 type A (formerly DIN 1142). If not specified in the order, wire rope clips according to DIN 741 will be supplied.

Technical details

| Cable diameter | Dimensional characteristics of the clips | Recommended number of clips per eyelet(*) | Required torque | Approximate linear mass | ||

| [mm] | D1 | H1 | A | [Nm] | [kg/100buc] | |

| 5 | M5 | 25 | 12 | 3 | 2 | 2,1 |

| 6,5 | M6 | 32 | 14 | 3 | 3,5 | 4 |

| 8 | M8 | 41 | 18 | 4 | 6 | 8,2 |

| 10 | M8 | 46 | 20 | 4 | 9 | 9,2 |

| 12 | M10 | 56 | 24 | 4 | 20 | 17,1 |

| 13 | M12 | 64 | 27 | 4 | 33 | 27,5 |

| 14 | M12 | 66 | 28 | 4 | 33 | 27,7 |

| 16 | M14 | 76 | 32 | 4 | 49 | 43 |

| 19 | M14 | 83 | 36 | 4 | 68 | 49 |

| 22 | M16 | 96 | 40 | 5 | 107 | 68 |

| 26 | M20 | 111 | 46 | 5 | 147 | 117 |

| 30 | M20 | 127 | 54 | 6 | 212 | 140 |

| 34 | M22 | 141 | 60 | 6 | 296 | 213 |

| 40 | M24 | 159 | 68 | 6 | 363 | 268 |

(*): Recommended method of securing a cable loop, including the positioning of the clips on the eyelet (the clips body is always fixed on the active side of the loop):