Welding

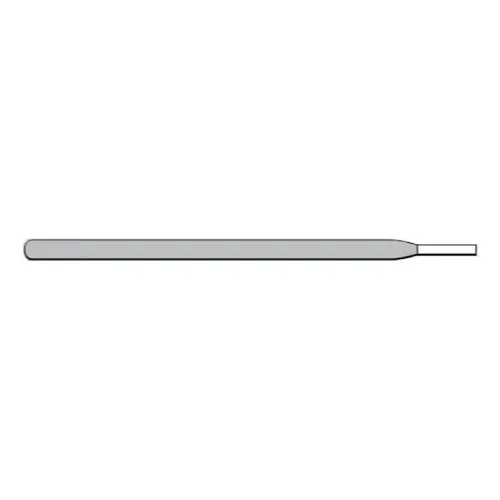

Welding Electrodes PATON – RUTILICI

Product details

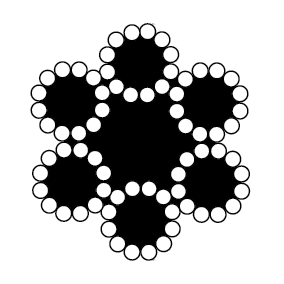

PATON Rutile electrodes are used for manual welding of carbon steels or low C steels (equivalent to St 0, St 1, St 2, groups A, B, C as well as grades of steels KP, PS, SP according to US 1050 – (05kp, 08kp, 08ps, 08, 10kp, 10pc, 10, 15kp, 15ps, 15, 20kp 20ps, 20). Welding is possible in any position, except vertical down position for electrodes of 5 mm diameter. The electrodes are characterized by easy ignition and re-ignition, stable burning, few metal losses through splashing, continuous and proportional weld seam; continuous deposited metal, with easy slag separation. They allow the use of low amperage electric current. Small diameter electrodes can be used with household power sources. The electrodes are easy to handle, making them user-friendly even for amateur or beginner welders. The electrodes are not sensitive to the quality of edge preparation, availability of galvanized coatings, rust, and other surface contaminants.

Rutile-coated electrodes produce large droplet transfer, and the arc produced is stable and quiet at lower current intensities, making these electrodes suitable for welding thin sheets. Rutile-coated electrodes are suitable for welding in any position, except vertical down position.

Coating type: rutile

Standardization: AWS A 5.1:E 6013

Coding: 43 2 RС11 according to ISO 2560-A

Chemical composition of the welded metal (%):

PATON Rutile electrodes are used for manual welding of carbon steels or low C steels (equivalent to St 0, St 1, St 2, groups A, B, C as well as grades of steels KP, PS, SP according to US 1050 - (05kp, 08kp, 08ps, 08, 10kp, 10pc, 10, 15kp, 15ps, 15, 20kp 20ps, 20). Welding is possible in any position, except vertical down position for electrodes of 5 mm diameter. The electrodes are characterized by easy ignition and re-ignition, stable burning, few metal losses through splashing, continuous and proportional weld seam; continuous deposited metal, with easy slag separation. They allow the use of low amperage electric current. Small diameter electrode

| Mn | C | Si | P | S |

| 0,40-0,65 | Max. 0,11 | 0,10-0,35 | Max.0,035 | Max.0,030 |

Rutile-coated electrodes produce large droplet transfer, and the arc produced is stable and quiet at lower current intensities, making these electrodes suitable for welding thin sheets. Rutile-coated electrodes are suitable for welding in any position, except vertical down position.

Coating type: rutile

Standardization: AWS A 5.1:E 6013

Coding: 43 2 RС11 according to ISO 2560-A

Mechanical properties of the welded metal:

| Tensile strength N/mm² | Elongation at break % | Impact strength J/cm² |

| min.450 | ≥22,0 | ≥78 |

Specific characteristics:

Welding in any position is possible without modifying the welding current during the welding process. Welding vertical joints by the vertical down method should be done with a short arc or a short-circuiting contactor. Molten weld metal is not allowed to flow under the welding arc. This requires tilting the electrode angle/position to vertical at 40°-70°. In the downward position, an electrode should be tilted at an angle of 20° – 40° to the vertical.

Welding conditions:

| Electric current amperage (A), depending on the diameter of the electrodes (mm) | |||

| 2,5 | 3 | 4 | 5 |

| 50-100 | 80-110 | 130-140 | 170-230 |

Packaging method:

Boxes of 2.5 / 5 kg, and 1 kg for diameters of 2.5 – 3 mm

Welding positions

Manufacturer's certificate:

| Producer | Origin | Certified product | Certificate № |

| LLC “Pilot Plant E.O.Paton” | Ucraina | Consumabile pentru sudură: standard general pentru metale de umplere și flux metalic pentru sudarea materialelor: electrozi acoperiți pentru sudarea manuală cu arc electric conform EN ISO 2560 și EN ISO 3581, certificare CE conform EN 13479 | 1922-CPR-0998 |

Bibliography:

SR EN ISO 2560:2010: Welding materials. Covered electrodes for manual arc welding of non-alloy and fine-grained steels. Classification.

SR EN ISO 14341:2011: Welding consumables. Wire electrodes and deposits for gas-shielded metal arc welding of non-alloy and fine-grained steels. Classification.