Oils and greases

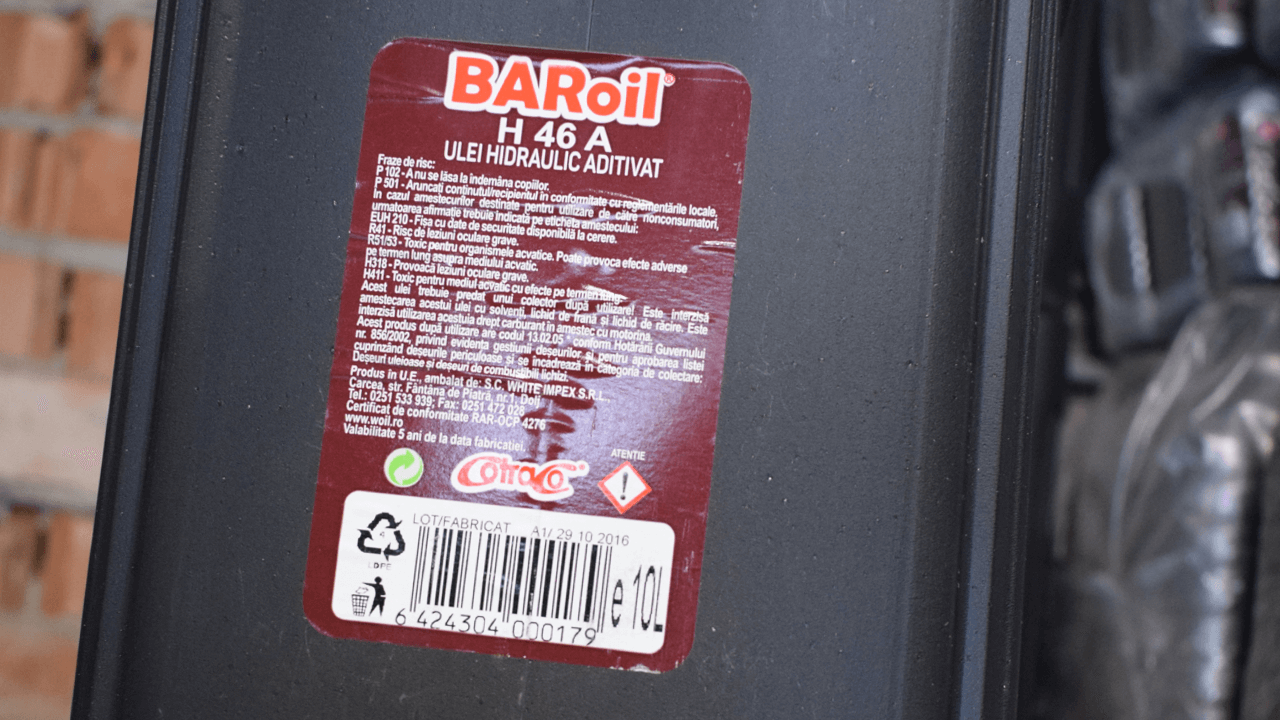

Hydraulic oil Baroil® H46 A

Product details

Additized hydraulic oils are obtained from refined base oils and additives that give them antioxidant, anti-rust, anti-wear, antifoaming, and demulsifying properties. The products meet the conditions of the specifications: DIN 51524 / Part 2 HLP, AFNOR NF E 48-603 HM, Sperry Vickers I-286-S; Denison Filterability TP 02100, US Steel 126; US Steel 127, STAS 12023-82. The quality conditions, extracted from ST 16/2007, are as follows:

Observations

Packaging, marking, storage, transport, and handling are done according to STAS 4225 and internal instructions/procedures.

Packaging method: 1 liter – 3 liters – 5 liters – 10 liters – 20 liters; 200 liter drum.

The warranty period is 5 years from the date of manufacture.

Application Areas

It is used as a working fluid in hydraulic systems, power transmission systems, equipped with pumps and motors for high pressures, with axial or rotary pistons, high-speed gears, speed variators, hydraulic couplings, etc., according to the operating instructions specified in the technical manual of each piece of equipment.

Technical details

| No. | Characteristics | Admissibility conditions | Testing method |

| ISO viscosity grade | VG46 | SR ISO 3448 | |

| 1 | Density, at 15 o C, g /cm3 | Max.0,895 | SR EN ISO 12185 ASTM D 4052 |

| 2 | Kinematic viscosity at 40°C, mm²/s1 (cSt) | 41,4-50,6 | SR EN ISO 3104 ASTM D 445 |

| 3 | Viscosity index | Min.90 | STAS 55 ASTM D 2270 |

| 4 | Flash point, °C | Min.205 | SR EN ISO 2592 ASTM D 92 |

| 5 | Pour point, °C, ** | Max.-15 | STAS 6170 ASTM D 97 |

| 6 | Demulsification time for 40 - 37 - 3 ml / minutes | Max.30 |

STAS 56 (method II) ASTM D 1401 |

| 7 |

Foaming properties: Tendency to foam – foam stability Foam volume after 5 minutes of blowing air, cm³, max.

|

50-0 50-0 50-0 |

SR ISO 6247+C1 ASTM D 892 |

| 8 | Corrosive action on copper strip. 3 hours at 100°C | Max.1 b | SR EN ISO 2160 ASTM D130 |

| 9 | Rust protection capacity for steel | No traces of rust | SR ISO 7120 ASTM D 665 ( A) |

| 10 |

High-pressure resistance on the four-ball machine: Mechanical wear:

|

Max.0,4 | STAS 8618 ASTM D 2783 |

| 11 |

*Long-term oxidation stability after 1000 hours:

|

Max.2 | STAS 9848 ASTM D 943 |

| 12 | *High-pressure resistance on the FZG gear test machine: | Min. 10 | DIN 51354 Part2 |

*This characteristic is guaranteed through manufacturing technology.