Wire Ropes

Steel wire ropes, standard construction 6×19+FC

Product details

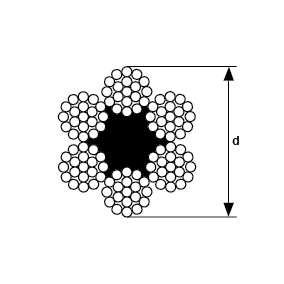

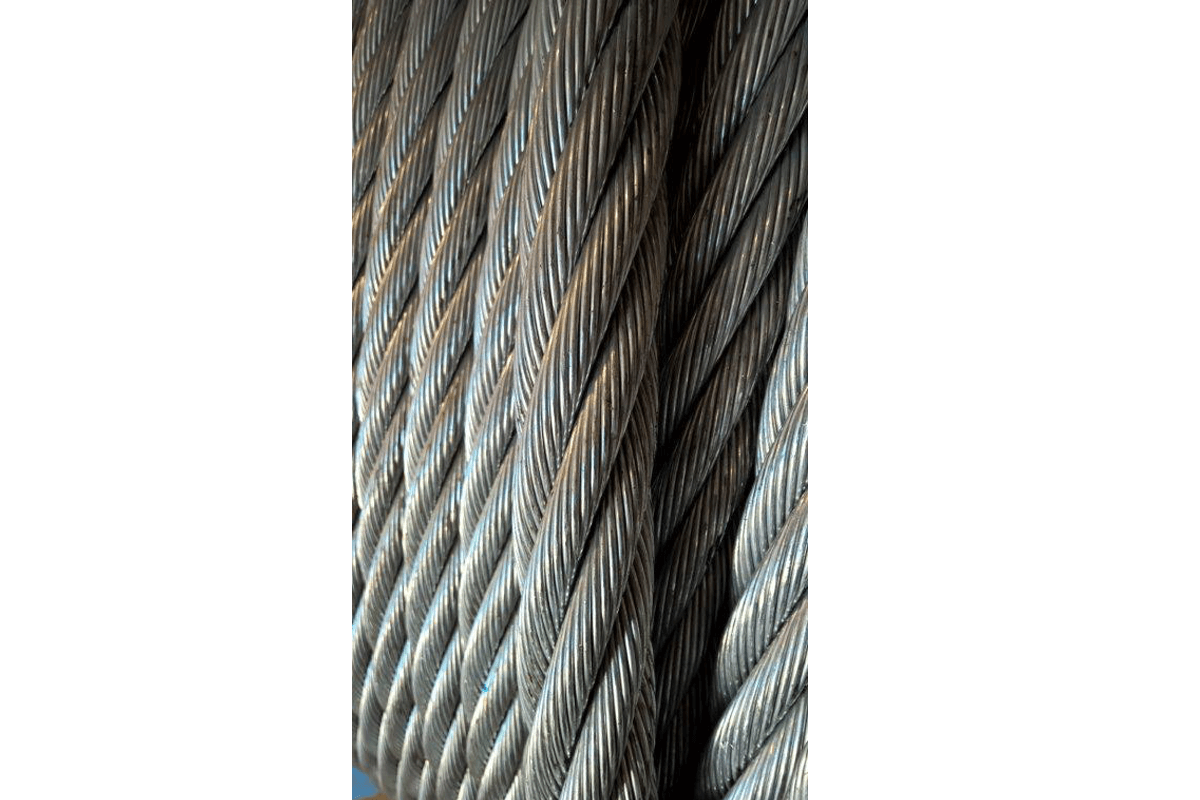

Steel wire ropes, produced by winding of 6 strands construction 1×19 Seale around a fiber core (hemp, sisal, polypropylene). Quality and delivery condition according to EN 12385-4. Delivery in bright or galvanized condition. his is a combined construction, as into a strand there are lays of wires of different diameter, the outer lay is with larger diameter of wire, so that the resistance to friction is increased. The fill factor in strand is higher than for the standard rope, so the mechanical characteristics are better.

Application Areas

Forestry, aviation, cranes, drilling, draglines, fishing, guy ropes, lifting, offshore, slings, winches, other industrial purpose.

Technical details

| Nominal diameter | Unit weight | Minimum breaking load | |

| [mm] | [kg/100m] | 1770N/mm2 | 1960N/mm2 |

| 5 | 8.7 | 13.6 | 15.0 |

| 6 | 12.5 | 19.6 | 21.7 |

| 7 | 17.0 | 26.6 | 29.5 |

| 8 | 22.1 | 34.8 | 38.5 |

| 9 | 28.0 | 44.0 | 48.7 |

| 10 | 34.6 | 54.3 | 60.2 |

| 11 | 41.9 | 65.8 | 72.8 |

| 12 | 49.8 | 78.2 | 86.6 |

| 13 | 58.5 | 91.8 | 101.7 |

| 14 | 67.8 | 106.5 | 117.9 |

| 15 | 77.9 | 122.3 | 135.4 |

| 16 | 88.6 | 139.1 | 154.0 |

| 17 | 100.0 | 157.0 | 173.9 |

| 18 | 112.1 | 176.1 | 195.0 |

| 19 | 124.9 | 196.2 | 217.2 |

| 20 | 138.4 | 217.4 | 240.7 |

| 21 | 152.6 | 239.6 | 265.4 |

| 22 | 167.5 | 263.0 | 291.2 |

| 23 | 183.0 | 287.5 | 318.3 |

| 24 | 199.3 | 313.0 | 346.6 |

| 25 | 216.3 | 339.6 | 376.1 |

| 26 | 233.9 | 367.3 | 406.8 |

| 28 | 271.3 | 426.0 | 471.7 |

| 30 | 311.4 | 489.1 | 541.5 |